Huxley Bertram to attend CMAC Open Days 2023

We are happy to announce that Huxley Bertram will be at the CMAC…

Huxley Bertram at The Canmaker Summit 2023

It was exciting to attend this year's Canmaker Summit in Edinburgh.

Being…

HB50 Tablet Compaction Simulator at Making Pharmaceuticals UK 2023

HB50 Tablet Compaction Simulator at Making Pharmaceuticals…

Compaction Simulation Forum 2022

Compaction Simulation Forum 2022

The Compaction Simulation Forum…

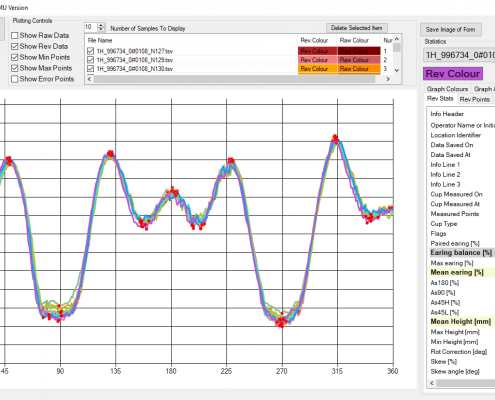

Automatic Cupping & Earing Measurement Unit featured in Aluminium International Today

Automatic Cupping & Earing Measurement featured in Aluminium…

Join Huxley Bertram at the Compaction Simulation Forum

Compaction Simulation Forum, 7th to 9th November 2022, France

As…

Compaction Simulation Research and Services

CMAC Partners with Huxley Bertram to Provide Compaction Simulation…

Compaction Simulators Under Containment

Huxley Bertram Commission Multiple Compaction Simulators In North…

Work Placement Week 2022

Work Placement Week for Year 10 Students.

Huxley Bertram welcomed…