Not on your Ear Lobe:

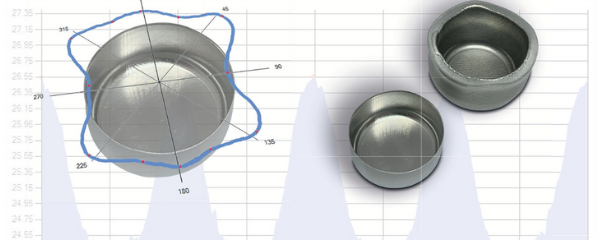

Earing is a metallurgical property of rolled metal sheet typically used in the beverage can industry. Earing manifests as a wavy profile at the rim of a deep‑drawn cup; instead of forming a flat, level edge, the cup’s rim forms regular peaks and troughs—each peak is an “ear,” and a full “ring” of “ears” is “earing”. The underlying material property responsible for earing is planar anisotropy: the rolling process used to form sheet metal causes material properties to vary parallel and perpendicular to the rolled direction. The metallurgical “texture” of the metal is altered, with alignment of the grain structure changing the ductility of the sheet and causing different strain rates in a drawing process. Ears occur at specific angles in patterns of 4, 6, or 8 ears around the cup’s edge. This property is most pronounced in rolled aluminum but is also pertinent in sheet steel (referred to as “Tinplate” in Canmaking) and in other non-ferrous rolled metals.

Earing or Earring?

Earing is also sometimes written as “Earring” but to differentiate from skin puncturing lobe ornaments we use “Earing”. The measurement of Earing is measuring a metallurgical property, like tensile strain, inherent to a rolled sheet of metal.

Why Earing Matters

Earing is far more than a cosmetic effect. The type, number, height, and angular position of ears reveal important cues about grain structure, formability, and the consistency of the sheet. In the beverage can supply chain, at rolling mills, mean earing is often a release criterion for coils because excessive earing means more trim waste, can bodymaker jams and necking failure due to Necker pleats. Canmaker’s quality control departments monitor their suppliers’ earing properties to prevent stoppages on the can production line. In sheet rolling mills metallurgists use earing properties to understand and control metallurgical texture during rolling process development. Every minute of downtime on a canmaking line is critical so manufactures place a strong emphasis on earing measurement.

How Earing is Measured (and Why Method Matters)

Historically, measurement was performed with contact probes that trace the ‘ears’ of a drawn cup while the cup rotates. But physical contact will oftendeform thin rims and lose fine features. Modern systems therefore use contactless laser measurement to capture the full 360° profile with micron‑level precision, preserving delicate details and improving repeatability. Results are typically displayed as polar and Cartesian plots, with derived metrics such as mean earing (%), max/min, ear count, and angular positions in line with EN 1669 / ISO 11531 methodologies.

The press – the heart of earing measurement.

Historically, presses used for earing have been designed following “cupper” presses used in canmaking, however cupper presses are designed to minimise earing whereas earing presses need to reveal and promote the earing property.

The Huxley Bertram EP100 series presses utilise tooling designed to keeping cup walls straight while eliminating ironing of the cup walls, providing cups that are as short as possible to reveal the true earing value. Cupper presses deliberately pinch the cup edge to elongate it, whereas an earing press must release the sample material just before the earing edge is pinched. The EP100 precisely maintains sample clamp force during draw and then releases it in less than 100ms.

Common Mistakes in Earing Measurement

Even with modern tools, errors creep in. Here are the most frequent pitfalls:

- Inappropriate/Uneven Sample lubrication – HB Earing Lubricants allow consistent results even with hand application.

- Uneven/Imprecise blank clamping – leading to skewed ear height and angular positions.

- Inconsistent forming conditions – such as lubrication and blank centering, which distort results.

- Manual data handling – introducing transcription errors and traceability gaps.

- Over-reliance on single-point checks – missing full-profile anomalies.

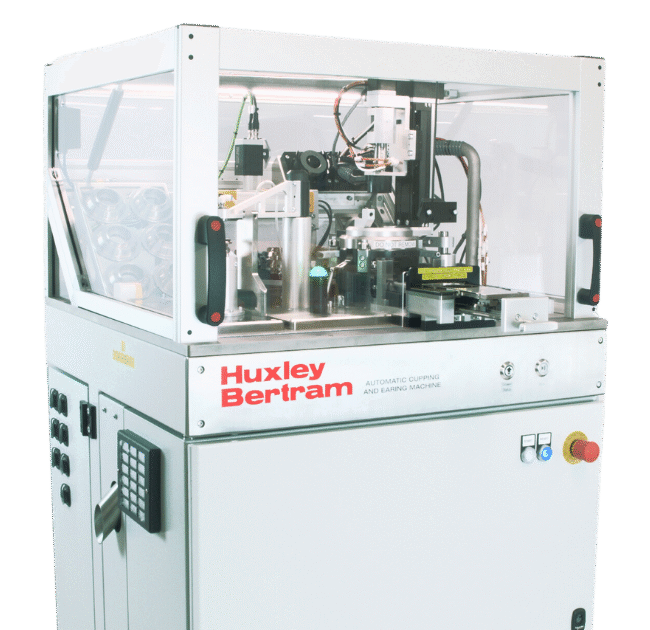

How Huxley Bertram Solves These Challenges

Our systems are designed for reliable and repeatable earing measurement, not just compliance. Here’s how:

- Deskew algorithm automatically corrects misalignment, eliminating false ear height inflation.

- Controlled forming with EP100 Earing Press ensures consistent cup geometry for accurate comparison.

- Automated data capture and reporting reduces human error and provides full traceability.

- Advanced analysis software validates symmetry, detects anomalies, and flags outliers before they become costly issues.

Built With the Industry, For the Industry

We’ve collaboratively worked with rolling mills and canmakers worldwide, refining tooling, measurement methods, and analysis to solve real-world challenges. That partnership-led approach is why customers trust us for reliable, repeatable earing measurement that stands up to daily use and audit scrutiny.

Going Beyond EN 1669 Standards

EN 1669 and ISO 11531 define the traditional baselines for earing measurement, but these have long been seen by industry to not give repeatable earing results. Huxley Bertram goes further. Our systems don’t just comply—they enhance accuracy, repeatability, and traceability through advanced algorithms, automated validation, and integrated data workflows. This ensures that your results are not only standards-compliant but also production-ready and audit-proof, giving you confidence in every decision.

Next Steps

Looking for the latest in earing measurement systems? Explore how our solutions—from forming with the EP100 Earing Press to rapid, contactless measurement with the Mini Earing Gauge (MEG)—deliver unmatched accuracy and speed.

Learn more about our earing testing and earing test machine solutions here: https://huxleybertram.com/earing-measurement-solutions/

+44 (0)1223 203160

Huxley Bertram Engineering Ltd.

53 Pembroke Avenue

Waterbeach

Cambridge

CB25 9QP

England