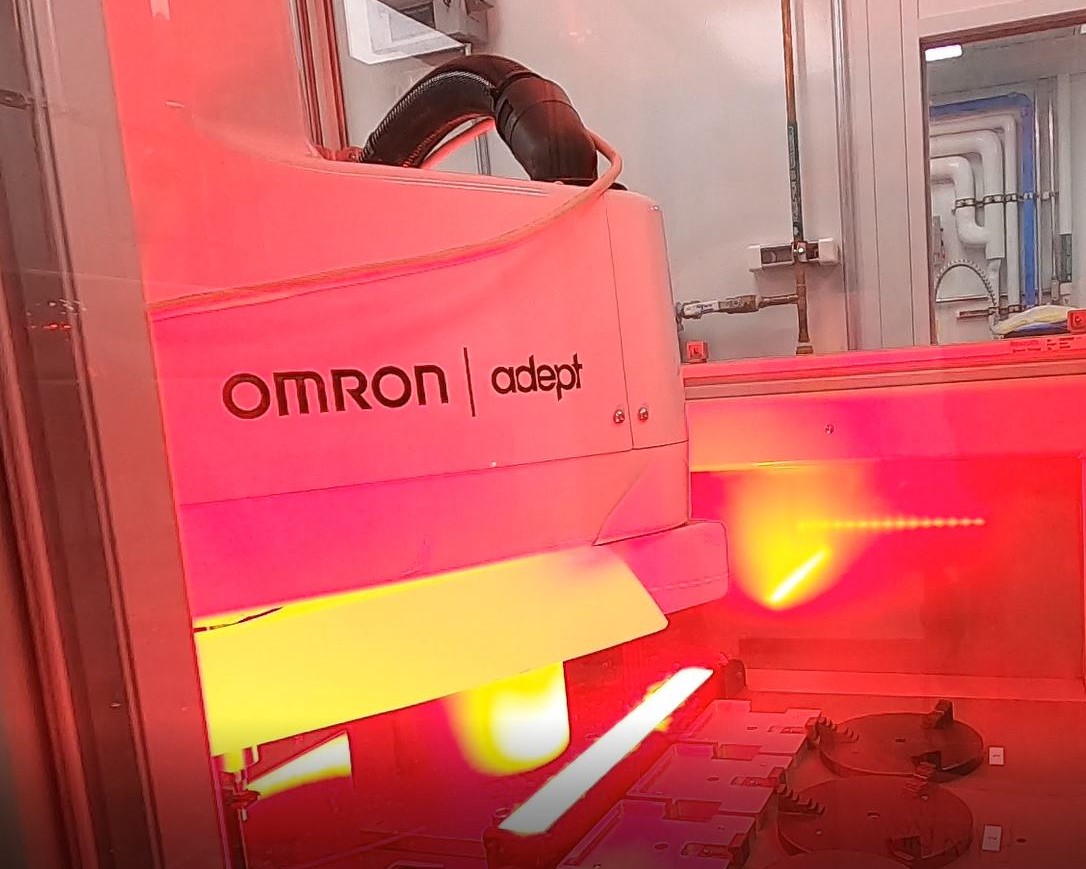

System for Crystallisation of Active Pharmaceutical Ingredient (API)

This system is highly confidential and only limited details are disclosable. The client is an international pharmaceutical company.

The project commenced with a joint proof of concept and development phase. This in turn led to a multi-million phase project to design, build, test and commission a bespoke pharmaceutical crystallisation system used in API manufacture. The unit has been commissioned and is successfully running in the client’s production.

The system was designed by Huxley Bertram and incorporates liquid delivery and crystallisation at low temperatures. The unit included PLC based control connecting to the clients SCADA and delivering data to an electronic batch record system.

Documentation on the project included:

- Functional Design Specification

- Factory Acceptance Test

- Spares

- Material Trace-ability for all Critical Process Items

The whole project required comprehensive project management, including its own HBEL customer specific quality plan. The system was GAMP5 compliant.