https://huxleybertram.com/wp-content/uploads/2021/09/CEMU-Website-Thumbnail.png

352

352

admin

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

admin2021-09-08 13:30:362022-11-09 09:34:11New Contactless Earing Measurement Brochure Completed

https://huxleybertram.com/wp-content/uploads/2021/09/CEMU-Website-Thumbnail.png

352

352

admin

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

admin2021-09-08 13:30:362022-11-09 09:34:11New Contactless Earing Measurement Brochure CompletedProduct Overview

Canmaking Industry Solutions, designed and built for the aluminium and beverage Canning industries.

Earing measurement solutions provide reliable and repeatable earing profile results for aluminium and aluminium alloys compliant with EN 1669 and ISO 11531.

Huxley Bertram offers two models of machine for Earing Measurement and one model for Wall Analysis: a Contactless Earing Measurement unit, an Automatic Cupping and Earing Measurement unit and a Contactless Can Wall Analysis Machine. All were developed in conjunction with leading Aluminium manufacturers worldwide.

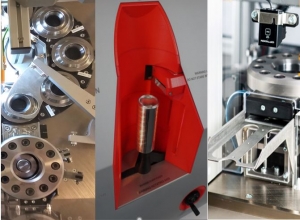

Huxley Bertram Earing Measurement System EP

Unlock a flexible, scalable approach to reliable, repeatable Earing measurement with our new modular Earing Measurement System. Built to adapt to evolving production and lab environments, the system brings together:

- Earing Press – precision‑engineered for high‑repeatability production of earing cups

- Mini Earing Gauge – quick, consistent, and easy‑to‑use measurement for confident data integrity

Enhance your workflow further with a range of modular upgrade options, allowing you to automate at your own pace:

- Cup Transfer – hands‑off handling for smoother, faster testing cycles

- Automatic Tool Changer – effortless switching between tooling for different sample types

- Integrated Lubricator – controlled, uniform lubrication for consistent test conditions

Together, these modules create a measurement solution that can grow from the base configuration to a fully automated system—aligned to your exact testing requirements.

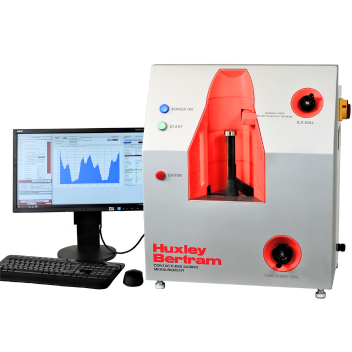

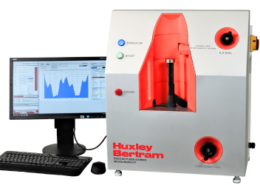

Contactless Earing Measurement Machine

A highly flexible, high speed and high accuracy, benchtop, Earing Measurement machine, adjustable to measure cups from 30 mm to 100 mm internal diameter and up to 150 mm tall, with a measurement accuracy of 10 microns.

These machines are used by sheet metal manufactures and beverage can makers around the world. This is our second-generation machine with many of the first generation still being used around the world.

The machine has recently been remodelled to bring it right up to date with a state of the art controller and is provided with Huxley Bertram’s Advanced Earing Analysis Package with algorithms developed over years of earing experience to facilitate rapid and accurate earing analysis.

An expanded version of the machine for bigger cups is also available.

Mini Earing Gauge

The Mini Earing Gauge (MEG) enables high-speed Earing measurement.

Contactless laser measurement enables repeatable, accurate and rapid Earing measurement of Cups.

Measurement and Cup swapping takes approximately 4 seconds on Huxley Bertram’s MEG. Huxley Bertram’s MEG has the capability of measuring hundreds of cans an hour, from 33mm internal diameter and 12-43mm deep.

Changing format tooling is done with ease using only one bolt in a matter of seconds. The Huxley Bertram Mini Earing Gauge is compliant with EN 1669 and ISO 11531. Huxley Bertram has 30 years of experience in Earing measurement and has been supplying Earing equipment to clients across the globe.

Contactless Can Wall Analysis Machine

A highly accurate and detailed, benchtop, Wall Analysis machine, adjustable to measure cups from 33 mm to 100 mm internal diameter and up to 200 mm tall, with a measurement accuracy of 6 microns.

The Contactless Can Wall Analysis Machine uses white light confocal sensors to precisely measure the wall thickness of beverage Cans with unprecedented detail and accuracy.

The Can is measured internally and externally to the nanometer at any height and rotation along the vertical Can wall building up rings of data at user-specified intervals and heights. The ring thickness data are interpolated to produce wall thickness measurements.

Intended applications for the machine include top wall angle measurement, bodymaker misalignments, crosshatch wear detection, defect detection, Can design R&D, and many more.

Learn More About Earing Measurement

Watch the video: Learn more about earing test measurement and interpretation of results:

- How is an Earing profile measured

- What can I learn about metal quality from an Earing profile

- How are Earing profiles classified

- Recorded and ideal Earing profiles

- Tooling influences on providing an accurate Earing profile results

- Hidden pitfalls in Earing measurement

Read more: What is Earing? – Huxley Bertram

Automatic Cupping and Earing Measurement Machine

Watch the video: Showing the high-speed performance of the Automatic Cupping and Earing Measurement Machine, all within 20 seconds:

- Aluminium sample scanning with barcode and sample thickness measurement reader

- Deep drawing of the earing cup

- Final Earing profile measurement

- Earing Analysis and Results

Contactless Can Wall Analysis Machine

Watch the video: Learn more about the Contactless Can Wall Analysis Machine:

- Wall thickness analysed according to user-specified heights

- Top wall angle measurement

- Crosshatch evaluation

- Analyse surface detail

- Other applications: bodymaker misalignments, defect detection, Can design R&D, and many more

Earing Measurement Software

Advanced Earing Analysis Package

The Advanced Earing Analysis package allows our customers to analyse and simultaneously compare multiple earing profiles, generated on any of Huxley Bertram Earing Measurement machines.

The software is available on a standalone PC running Windows 7 or newer OS.