https://huxleybertram.com/wp-content/uploads/2026/01/Roell-Korthaus-AMSLER-machine.jpg

321

283

Fariz Rafar

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

Fariz Rafar2026-01-14 09:56:262026-01-14 11:25:07Moving from manual to automatic Earing measurement – What can modern Earing measurement techniques offer rolling mills?

https://huxleybertram.com/wp-content/uploads/2026/01/Roell-Korthaus-AMSLER-machine.jpg

321

283

Fariz Rafar

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

Fariz Rafar2026-01-14 09:56:262026-01-14 11:25:07Moving from manual to automatic Earing measurement – What can modern Earing measurement techniques offer rolling mills?30 YEARS YOUNG – LEGACY DEVICES ARE STILL COMMONPLACE

Manual measurement devices, such as the Roell + Korthaus AMSLER machine, are still frequently used in the rolled aluminium industry.

The AMSLER uses a combination of a four-point contact height gauge and summing mechanism to give a measurement of Earing for cups drawn from sheet material.

These devices are only able to give representative Earing measurements for ‘four peak’ metal. For ‘six peak’ metal, such as Can Body Stock, the four-contact-point design of the device fails to accurately capture all 6 peaks and valleys. For CBS, this typically results in a higher-than-expected reading, risking coils being rejected for falling outside of can-maker specifications.

Roell + Korthaus AMSLER machine

MEASUREMENT TO A TENTH OF A HUMAN HAIR

Huxley Bertram Mini Earing Gauge

Modern Earing measuring equipment, such as the Huxley Bertram Mini Earing Gauge, creates a detailed profile of an Earing cup using laser measurements. 360 points around the profile of a cup are measured to a repeatability of 10 microns.

Advanced software, proprietary to Huxley Bertram Earing measurement solutions, is then used to calculate cup Earing values. Any misalignment of the cup or skew due to the drawing process is automatically quantified and removed, and the Earing value is presented according to the internation standard for Earing measurement – EN1669.

RELIABLE, REPEATABLE – WHAT CAN USERS EXPECT AS THEY MOVE FROM MANUAL MACHINES TO MODERN EARING MEASUREMENT

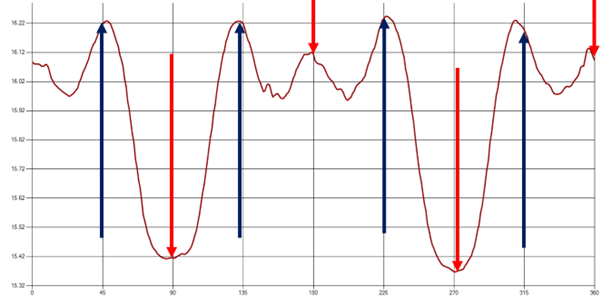

To answer this question, it is necessary to explain how Earing manifests in rolled aluminium. Can Body Stock typically produces a six-peak earing profile. This means that the edge of the cup exhibits 6 unique peaks of different heights, as well as 6 corresponding valleys. These peaks and valleys appear at defined angles relative to the metal grain – this occurs due to the superposition of metallurgical properties developed during both hot and cold rolling. For CBS, it is typical to see two particularly deep valleys perpendicular to the grain direction.

A graph of Earing measured for Can Body Stock, showing 6-peak Earing behaviour

In contrast, hot rolled material typically exhibits a four peak earing profile. Peaks and valleys always appear in pairs, and again with each pair being directly opposite each other on the cup.

AMSLER manual testing devices are designed to measure four peak material. When taking a manual measurement, the operator rotates the cup on the contact height gauge and records the highest Earing reading displayed over one rotation. This highest reading occurs when the contact points align with the peaks and valleys and because there are four measurement contact points, and four pairs of peaks and valleys, good alignment is possible. In this case the Earing value given by the device will approximate the EN1669 calculation.

There are, as always, some caveats – real Earing cups often show slight angular offsets in the locations of peaks and valleys. The graph below demonstrates how a device with contact points at fixed 90 degree spacing will fail to find the true deepest point of a valley and therefore give an inaccurate Earing value.

Hot rolled, four peak aluminium can be measured by an Acromat device

MODERN ROLLED MATERIALS REQUIRE MODERN MEASUREMENT SOLUTIONS

The EN1669 standard for measuring Earing gives us a set of formulas that are used alongside cup measurements to calculate the Earing value.

For Can Body Stock, calculating the Earing value requires all 6 peak and valley pairs to be measured. If an AMSLER device is used, the operator will find the highest Earing value when the contact points are aligned as below:

Hot and cold rolled Can Body Stock Earing can’t be measured by an Acromat device.

The red arrows, indicating the four valley contact points, do not align well with the Earing profile. For CBS, this measurement error results in the AMSLER reading being substantially higher than the EN1669 calculation.

| Typical CBS EN1669 Earing [%] | AMSLER Earing [%] | Difference in reading [%] |

| 2.78 | 3.3 | +0.52 |

For can body stock with a typical EN1669 Mean Earing of 2.75%, an AMSLER will typically give a reading of 3.24% – nearly 0.5% higher on average (Mean difference of 0.49% with a standard deviation of 0.09% for a dataset as measured by HB). As the specifications of can makers grow more demanding over time, this sort of error could well result in a good coil being rejected – a costly situation that can easily be avoided!

The Huxley Bertram Automatic Cupping and Earing Measurement machine, and Mini Earing Gauge offer Earing measurement to a repeatability as low as 0.07% EN1669.

Earing Measurement Machines

Contact us for more information

https://huxleybertram.com/wp-content/uploads/2026/01/Roell-Korthaus-AMSLER-machine.jpg

321

283

Fariz Rafar

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

Fariz Rafar2026-01-14 09:56:262026-01-14 11:25:07Moving from manual to automatic Earing measurement – What can modern Earing measurement techniques offer rolling mills?

https://huxleybertram.com/wp-content/uploads/2026/01/Roell-Korthaus-AMSLER-machine.jpg

321

283

Fariz Rafar

http://huxleybertram.com/wp-content/uploads/2018/07/Logo-e1459252101108.png

Fariz Rafar2026-01-14 09:56:262026-01-14 11:25:07Moving from manual to automatic Earing measurement – What can modern Earing measurement techniques offer rolling mills?

Huxley Bertram at The Canmaker Summit 2023

Automatic Cupping & Earing Measurement Unit featured in Aluminium International Today

+44 (0)1223 203160

Huxley Bertram Engineering Ltd.

53 Pembroke Avenue

Waterbeach

Cambridge

CB25 9QP

England