High Speed Tablet Compaction Simulator

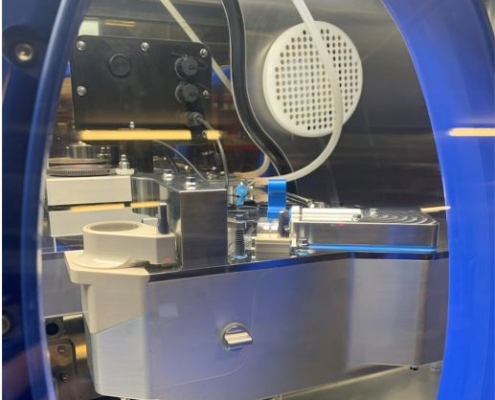

Huxley Bertram’s HB100 high-speed Tablet Compaction Simulator offers the highest level of containment up to OEB Level 5: allowing highly potent compounds to be analysed during the drug discovery and development stage. It can also be configured to meet individual OEL (Occupational Exposure Limits) µg/m3.

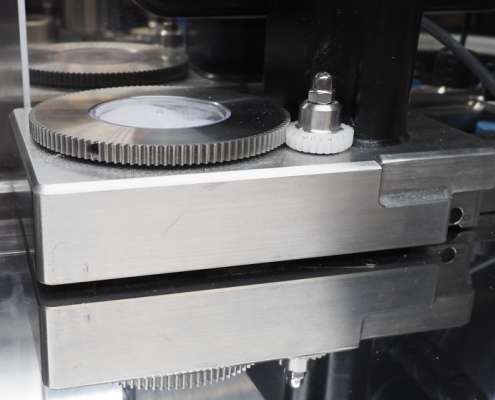

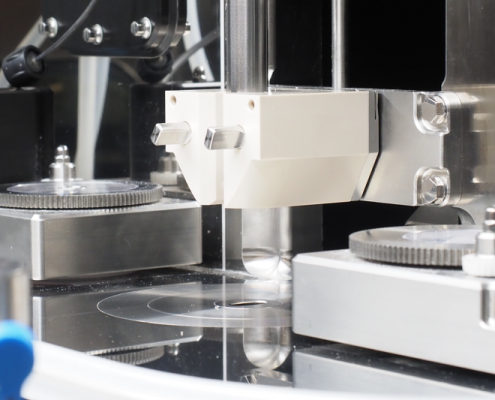

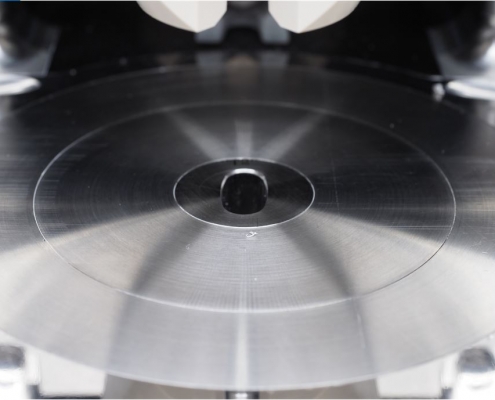

Mixed powder is delivered via the feed into the die and compacted. Multiple shaped dies are available, including square, circular, oval, and micro. Once formulated the tablets are automatically transferred for weighing, and thickness measurement. Breaking force measurement can be applied to determine the physical properties of the tablet formulation under compression.

Dual feeds allow for the production of multi-layer tablets critical to developing controlled release tablet formulations or where there may be chemical incompatibilities between active pharmaceutical ingredients.

All results are recorded by the comprehensive simulator control package, which can run in either “simulation” or “research” mode. The control package incorporates data export capabilities.

Drug Product Formulation scientists globally are using the high-speed Tablet Compaction Simulator to accomplish powder characterisation and assess /refine their suitability for full-scale production.

Additional information and videos can be found on the Tablet Compaction Product Page.